Reasons for cracking of PC sun board

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-10-19 18:05

- Views:

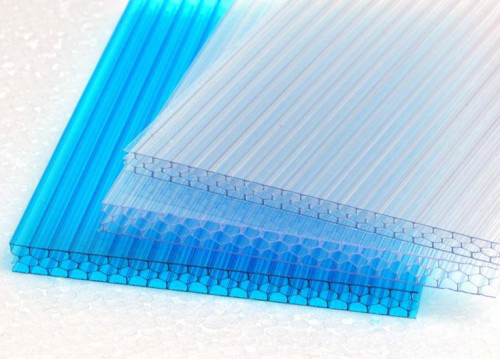

(Summary description)The internal stress in PC solar panels is formed in the process of extrusion molding and cooling and setting

Reasons for cracking of PC sun board

(Summary description)The internal stress in PC solar panels is formed in the process of extrusion molding and cooling and setting

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-10-19 18:05

- Views:

Information

The internal stress in PC solar panels is formed in the process of extrusion molding and cooling and setting, and in the process of placement or use where there is basically no change in their shape, they will experience a stress relaxation effect, which partially eliminates these applied forces. . However, it is difficult to completely eliminate these stresses in PC solar panels that only experience limited relaxation, and still retain a large internal stress in it, and then superimpose the external stress generated during use.

If the stress is too large, a local deformation zone of the surface layer will be generated and close to the surface, and easy break points (micro cracks, cracks) will appear from some places. Therefore, based on the above analysis of polymer physics theory, we must avoid those incorrect or excessive external stresses in the application.

1. During transportation and storage, it must be properly lined, packaged, and laid flat, because any slight damage (such as scratches) on the surface of the board will develop into a crack. And do not store the board and other chemical substances in the same place, because volatiles will cause chemical stress cracking on the surface of the board. The same must be done for the panels to be installed on the construction site.

2. Regardless of the type of processing, the processing knives or tools must not cause any damage to the non-processing parts of the plate, and the cut must be smooth. Because minor damage can also cause severe cracking.

3. The protective film shall not be damaged or removed before installation to avoid scratching the surface.

Fourth, it is never allowed to nail the plate directly to the frame, otherwise it will cause high stress due to the expansion of the plate and damage the edge of the perforation. The sealant and sealant gasket suitable for PC sunshine board plastic must be selected. Use wet sealant paste in wet assembly systems. It is generally recommended to use polysiloxane glue for the wet assembly of PC panels, but special attention must be paid to the chemical compatibility of the glue used before use. Do not use amino, aniline or methoxy curing agents to cure poly Silicone glue, because these curing agents can cause cracks in the board, especially when there is internal stress. Never use PVC as a gasket, because the plasticizer in PVC will precipitate and corrode the board, causing cracks in the performance and even damage to the entire board.

No.11 Hengtong Road, Tancheng Economic Development Zone, Linyi City, Shandong Province,China

Tel:0086 15017792129

E-mail:moonybm@outlook.com

Shandong Baike New Material Technology Co., Ltd. 鲁ICP备2020035293号-1 Power by:www.300.cn